Description

Build of Materials

Brass – DZR Brass 352 precision machined bar

O-Rings– twin Nitrile O-Rings Durometer Hardness Duro 70

Washer – Acetyl

Surface Finish – Chrome Plating

Filter – Nylon PA-66 & 304 Stainless Steel 40×40 Mesh Aperture 0.42mm

Flow and Pressure Operation

Operating pressure: Min 20kPa to Max 1600kPa.

Maximum pressure test for pipework pressure testing – up to 2000kPa.

Low pressure: for water pressures below 35kPa remove inline filter – Isovalve™ will have no effect on final flow rates when installed prior to a typical ceramic disc mixer.

At 20kPa a single Isovalve™ will deliver a minimum flow of 6.5L/min.

Operating pressure: At an operating pressure of 500kPa, a single Isovalve™ can deliver a maximum flow of approximately 33L/min.

Operating temperature range: short term minimum 0oC to maximum 90oC. Extended term 60oC.

Certification and Standards

Isovalves and accessories are manufactured and certified to comply with ATS5200.012, AS3688:2005 and ISO5208

DZR Brass complies with AS2345

WaterMark Certification pending.

Guarantee

Every Isovalve™ is factory tested before packaging. Isovalves are guaranteed against defective parts for a period of five (5) years.

Technical Downloads

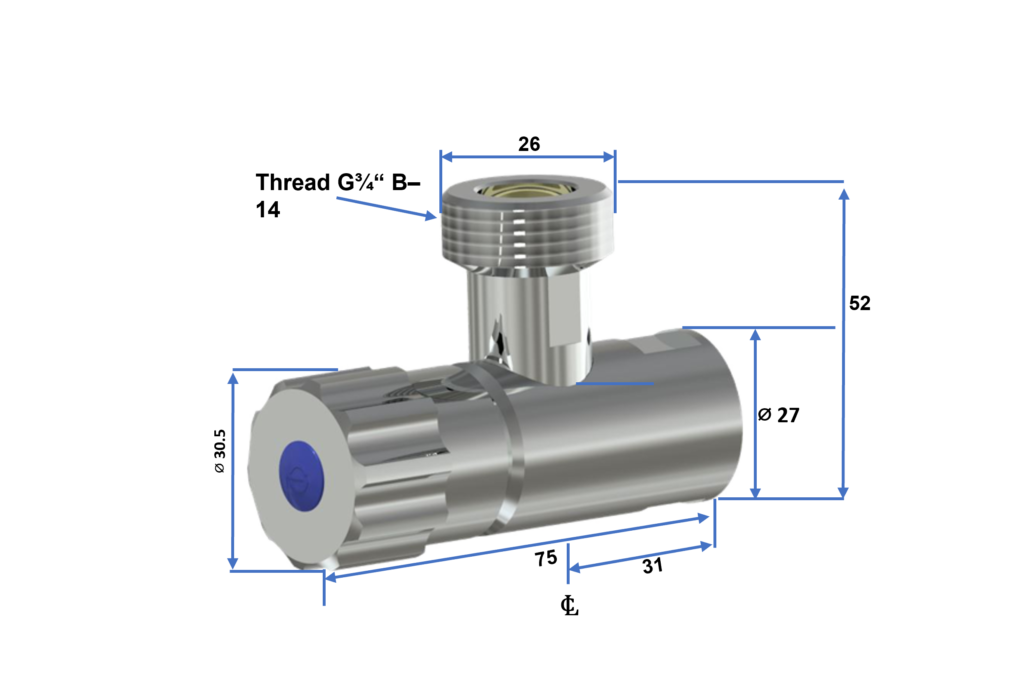

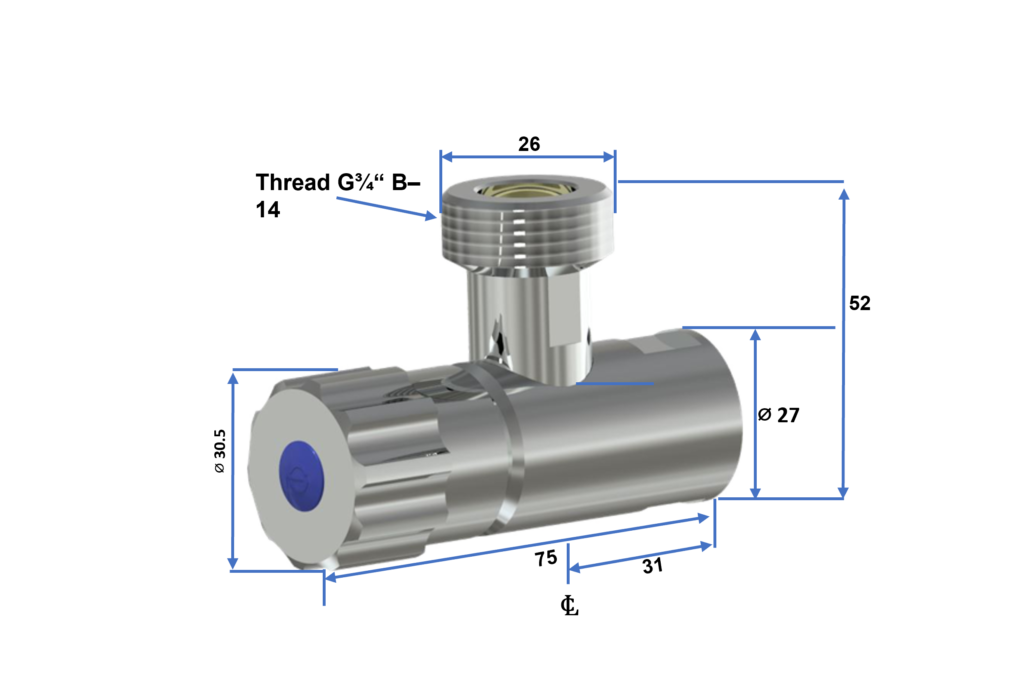

Link to Technical Specs: IsoTap20

Installation Instructions

IsoTap20

INSTALLATION INSTRUCTIONS

Conventional Install

Slide Wall Flange(IsoWFF) over IsoTap™

Apply sealant to male thread and screw on no more than 10mm DO NOT OVER-TIGHTEN

OR

Use IsoTap™ both as a tap and a temporary test plug.

The IsoTap™ Range can be used in place of a test plug by simply removing the outlet nipple and tap handle, leaving a cylindrical /lineal plug that can easily have wall linings etc drilled and installed over.

Instructions at Pre-Line Stage

Remove outlet nipple and tap handle.

Store carefully ensuring O-rings are not lost.

Plan installation considering finished wall thickness with outlet nipple.

Apply sealant and screw on IsoTap™.

Ensure IsoTap™ is closed and turn on water supply.

IsoTap20 can be used to pressure test to 2000 kpa and to flush out pipework. Protect chrome IsoTap™ with masking tape.

Instructions at Final Fit Off

There is no need to turn the water off at a remote location. Slide on wall flange (IsoWFF)

Screw on IsoNipple ensuring O ring and sealing surface is clean. Attach IsoTap™ handle.

Connect fixture. Turn on water at the IsoTap™

Adjust water to desired flow and commission.

10 (IsoN10) and 15mm (IsoN15) outlet nipples are available, enabling various configurations to suit.

Features:

Features: