Description

Build of Materials

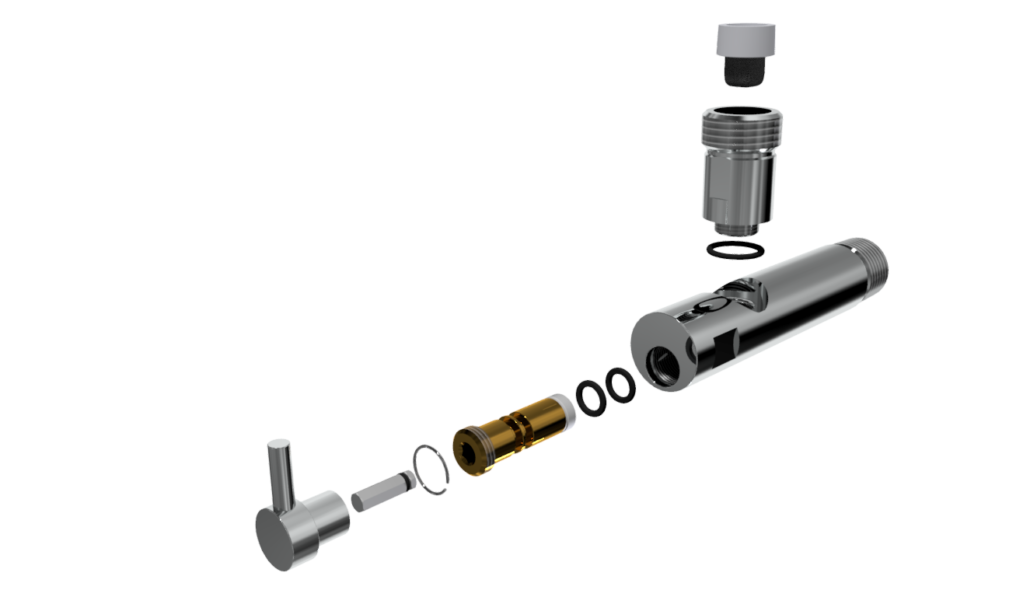

Brass – DZR Brass 352 precision machined bar

O-Rings– twin Nitrile O-Rings Durometer Hardness Duro 70

Washer – Acetyl

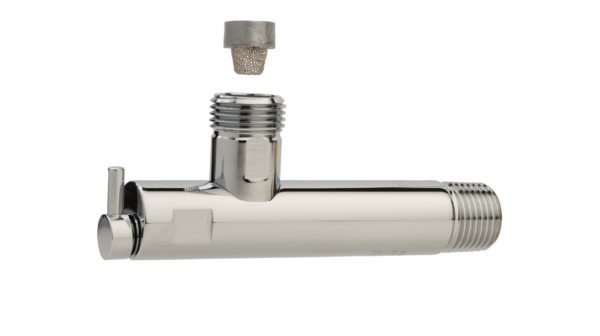

Surface Finish – Chrome Plating

Filter – Nylon PA-66 & 304 Stainless Steel 40×40 Mesh Aperture 0.42mm

Flow and Pressure Operation

Operating pressure: Min 20kPa to Max 1600kPa.

Maximum pressure test for pipework pressure testing – up to 2000kPa.

Low pressure: for water pressures below 35kPa remove inline filter – Isovalve™ will have no effect on final flow rates when installed prior to a typical ceramic disc mixer.

At 20kPa a single Isovalve™ will deliver a minimum flow of 6.5L/min.

Operating pressure: At an operating pressure of 500kPa, a single Isovalve™ can deliver a maximum flow of approximately 33L/min.

Operating temperature range: short term minimum 0oC to maximum 90oC. Extended term 60oC.

Certification and Standards

Isovalves and accessories are manufactured and certified to comply with ATS5200.012, AS3688:2005 and ISO5208

DZR Brass complies with AS2345

Australian WaterMark Certification Licence No. WM-022069.

Guarantee

Every Isovalve™ is factory tested before packaging and is guaranteed against defective parts for a period of five (5) years.

Technical Downloads

Link to Technical Specs: ISOVALVE MALE LONG

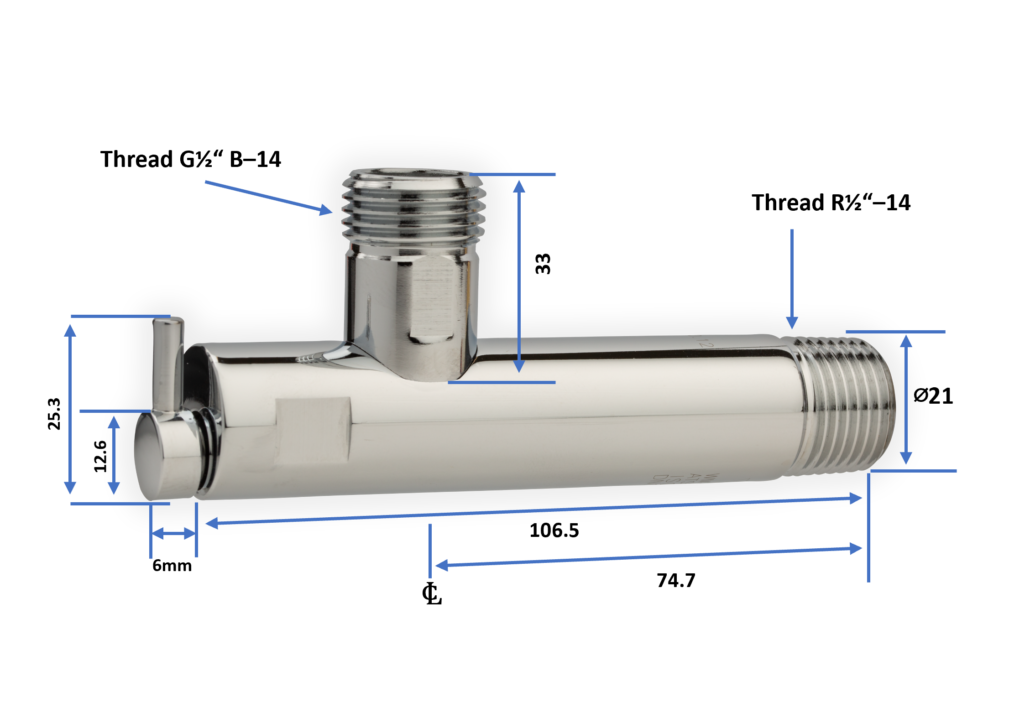

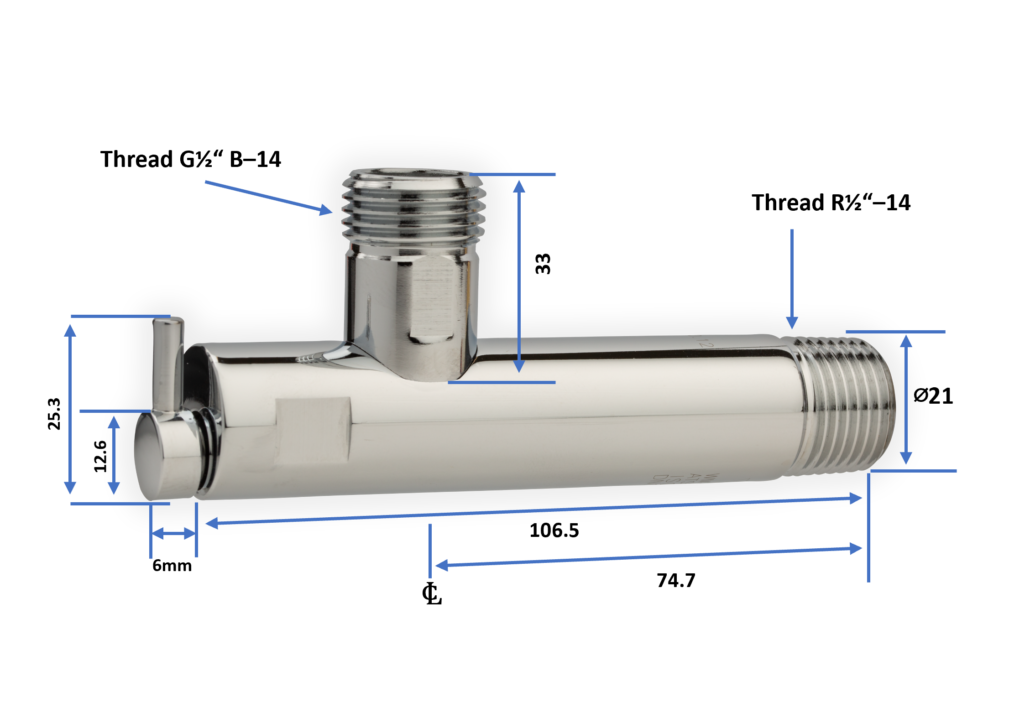

Measurements:

Installation Instructions

IsoVML – Appliance/Fixture Service Valve

Installing Isovalve™ in place of a Temporary Test Plug (First Fix)

The water mains need to be turned off for this part of the installation

Plan installation so that the IsoNipple (outlet) will be clear of wall lining or joinery. This may require an extension socket or the fixing for the bracket elbow may need to be brought forward.

- Remove protective sleeve, apply sealant to threads as required and tighten the Isovalve™ with a wrench.

- Ensure Isovalve™ is off by inserting Allen Key supplied and turning valve in a clockwise direction.

- Ensure all pipe work is complete and sealed off. Turn watermains back on, check for leaks. [Isovalve™ enables you to flush out pipe work at this stage – this is recommended as it removes foreign objects that will damage tapware and appliances]. Pipe work can be pressure tested through Isovalve™ up to 2oookPa.

- Slide on the protective sleeve, store IsoHandle (IsoKey), IsoNipple and IsoFlange until you are ready to fit fixtures.

Connecting the Isovalve™ to Fixtures (Second Fix)

- Remove protective cover.

- Slide over IsoFlange

- Screw in IsoNipple and secure O-ring seal with a wrench.

- Ensure IsoFilter is in place and attach pipe work from appliance/fixture.

- Turn on Isovalve™ with Allen Key to desired flow rate with water conservation in mind.

- Attach IsoKey or use tamper-proof dome.

10 (IsoN10), 15 (IsoN15) and 20mm (IsoN20) IsoNipples are available.