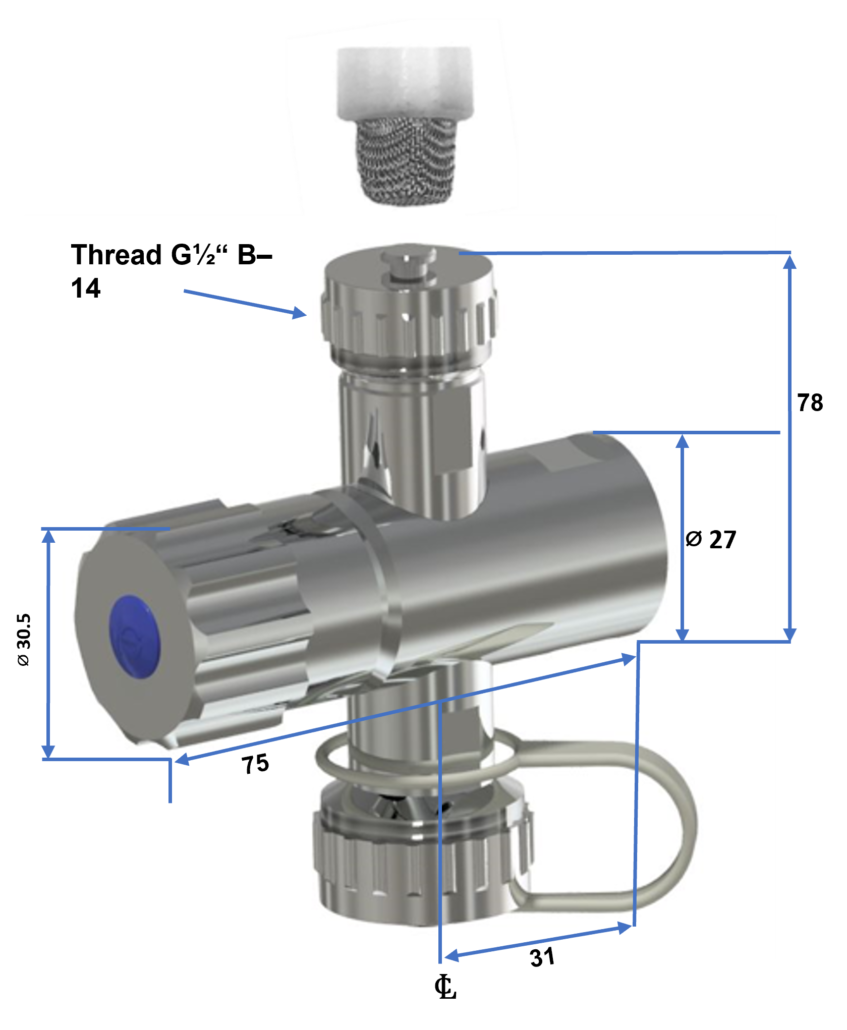

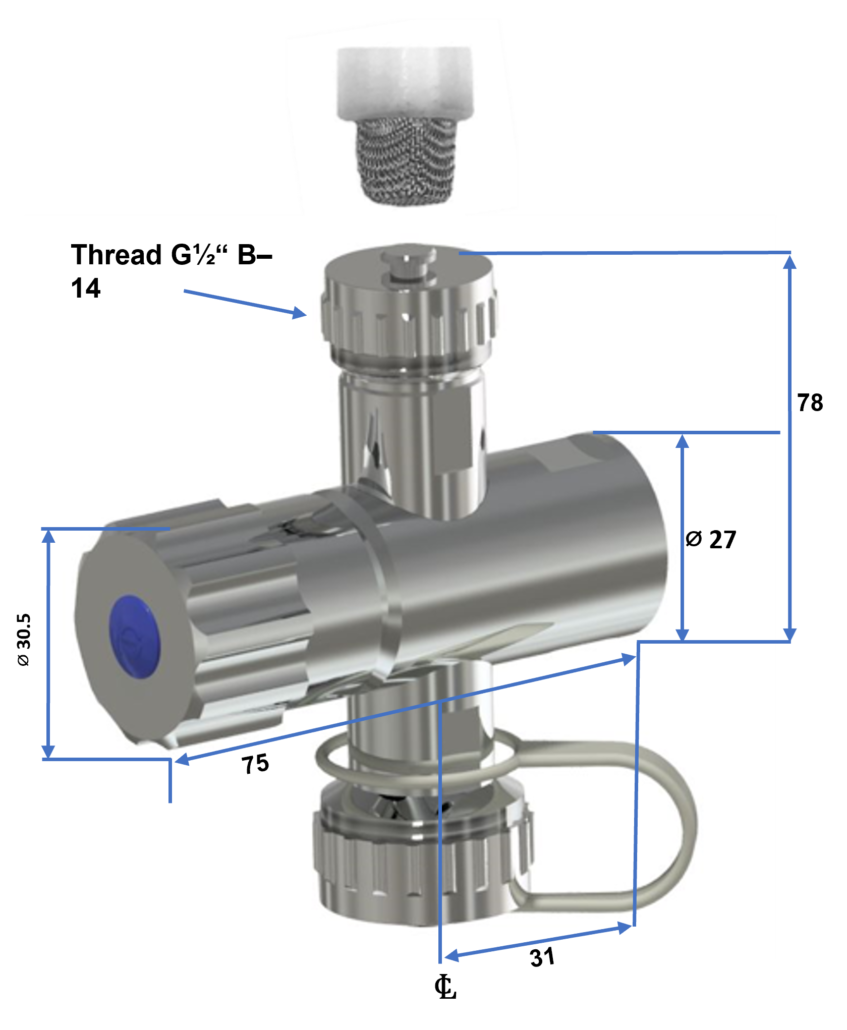

Description

Build of Materials

Brass – DZR Brass 352 precision machined bar

O-Rings– twin Nitrile O-Rings Durometer Hardness Duro 70

Washer – Acetyl

Surface Finish – Chrome Plating

Filter – Nylon PA-66 & 304 Stainless Steel 40×40 Mesh Aperture 0.42mm

Flow and Pressure Operation

Operating pressure: Min 20kPa to Max 1600kPa.

Maximum pressure test for pipework pressure testing – up to 2000kPa.

Low pressure: for water pressures below 35kPa remove inline filter – Isovalve™ will have no effect on final flow rates when installed prior to a typical ceramic disc mixer.

At 20kPa a single Isovalve™ will deliver a minimum flow of 6.5L/min.

Operating pressure: At an operating pressure of 500kPa, a single Isovalve™ can deliver a maximum flow of approximately 33L/min.

Operating temperature range: short term minimum 0oC to maximum 90oC. Extended term 60oC.

Certification and Standards

Isovalves and accessories are manufactured and certified to comply with ATS5200.012, AS3688:2005 and ISO5208

DZR Brass complies with AS2345

WaterMark Certification pending.

Guarantee

Every Isovalve™ is factory tested before packaging. Isovalves are guaranteed against defective parts for a period of five (5) years.

Technical Downloads

Link to Technical Specs: IsoAppTap2015

Installation Instructions

IsoAppTap2015

INSTALLATION INSTRUCTIONS

Conventional Install

Slide Wall Flange(IsoWFF) over IsoAppTap. Apply sealant to male thread and screw on no more than 10mm DO NOT OVER-TIGHTEN

OR

Use IsoAppTap both as a tap and a temporary test plug.

The IsoTap™ Range can be used in place of a test plug by simply removing the outlet nipple and tap handle, leaving a cylindrical /lineal plug that can easily have wall linings etc drilled and installed over.

Instructions at Pre-Line Stage

Remove outlet nipple and tap handle.

Store carefully ensuring O-rings are not lost.

Plan installation considering finished wall thickness with outlet nipple.

Apply sealant and screw on IsoAppTap.

Ensure IsoAppTap is closed and turn on water supply.

IsoAppTap2015 can be used to pressure test to 2000 kpa and to flush out pipework. Protect chrome IsoAppTap with masking tape.

Instructions at Final Fit Off

There is no need to turn the water off at a remote location. Slide on wall flange (IsoWFF); Screw on IsoNipples ensuring O ring and sealing surface is clean. Attach IsoAppTap handle.

Connect fixture. Turn on water at the IsoAppTap.

Adjust water to desired flow and commission.

10 (IsoN10), 15 (IsoN15) and 20mm (IsoN20)outlet nipples are available, enabling various configurations to suit.

The 15 & 20 Caps are fitted hand tight – if applying water pressure please ensure these are tool tightened.

Features:

Features: